8.1 KiB

Preparation and Cost

Get all the parts / raw material

-

For the 3D printing there are two options:

- Filament, which is the basis for 3D printing. Luckily I could print at my work-place which reduced the cost from 210€ to 70€. The kind of filament you need depends on the 3D printer you have available.

- Buy the printout of adareth's model at shapeways for 210€ over here http://www.shapeways.com/designer/adereth/creations

-

Decide on the switches

- If you are going to invest a whole lot of time and money for a custom keyboard instead of buying one for 10€ I'd recommend to use your favorite switch-type. To make a well-informed decision I bought a switch-tester for this from massdrop and decided on Cherry MX Whites. https://www.massdrop.com/buy/varmilo-switch-tester-with-anodized-case

- I ordered 70 Cherry MX Whites from here: https://mechanicalkeyboards.com/shop/index.php?l=product_detail&p=847

-

Decide on the key caps

- On the glamour-Shot you can see the 1976 keycap set, it used to be sold over here: http://pimpmykeyboard.com/sa-1976-keycap-set/ but the link is dead right now. You could try this link: https://www.massdrop.com/buy/nineteenseventysix-sa-keycap-set but it is a massdrop which is way different from usual online-stores. If you find a site that sells these make sure you get the right amount and type of keys according to the layout

- I got the "TKL Base Set + TKL Modifier" from over here: http://pimpmykeyboard.com/dsa-pbt-abs-blank-keycap-sets/ but I'm still two long keys short, I will have to order those specifically and I have a bunch of keys I don't use left-over.

-

The USB-Cable that connects the keyboard to your computer

- It's an USB 2.0 to USB Mini-B cable, make sure you get one that is 2 meters long, it really makes handling the keyboard so much more comfortable

- https://www.amazon.de/gp/product/B00NH11N5A/

-

The main controller (right half)

- A Teensy 2.0, I got that one from here: https://www.pjrc.com/store/teensy.html

-

The chip, connectors and cable to give life to the left half

-

TTRS cable and jacks

- Got my TTRS cable from here: http://www.digikey.de/product-search/de?keywords=839-1257-ND

- Got my TTRS jacks from here: http://www.digikey.de/product-search/de?keywords=CP-43514-ND

-

MCP23018 16 bit IO Expander

- Got mine from here: http://www.digikey.de/product-search/de?keywords=MCP23018-E%2FSP-ND

-

What I spend on my keyboard (should give you a rough estimate for your build):

| item | cost |

|---|---|

| filament | 70 |

| switch-tester | 30 |

| key-caps | 70 |

| teensy 2.0 | 30 |

| switches | 60 |

| usb cable | 10 |

| IO Expander, TTRS jacks and cable | 30 |

| overall cost | 300 |

My choices / advantages:

- Using the soldering iron at the uni-workshop for free

- 76 Diodes for free

- Soldering wire and copper for free

- All the resistors used for free (5 resistors are used)

- Several files for working out the rough edges of the 3D-printout

Depending on what you have available you might spend more or less money than me, 300€ however is a good rough estimate.

After all the parts have arrived it is safe to move on to the next section.

Wiring

It is assumed that you have printed the casing successfully, I had alot of help for this so I'm not going into advice on 3D printing here.

- Plug the switches into the Casing, no glue is needed, the casing provides the perfect fit.

-

Put the keycaps on the switches

- Note that in the pictures here some of the long keys on the thumb-part are too short, that's why it doesnt look symmetrical

Now going further on in the guide there are two options

-

The first option is to print flexible PCBs. The advantage is that you save alot of wiring business, everything looks rather clean and you dont have to worry about your cables being too thick such that the casing doesnt close. However if you don't have the means to print out such PCBs there is the second option, hand-wiring everything by hand.

-

The guide for this is very rough indeed and it doesnt include the firmware used. Wiring and firmware play extremely close together, wiring before knowing your firmware is like buying a shoe without measuring your feet before. For this option information about the exact firmware is not published, this in addition to the fact that the pictures in this rough guide are incomplete makes this option extremely beginner-unfriendly. Going in blind-sided like this may lead to one of these things:

- reprogramming huge parts of the firmware to match your wiring which comes with a ton of debugging

- rewiring to adapt to what the firmware expects, which may easily double your work here

-

-

The second option is to hand-wire everything. For people like me who had never soldered before this was great pain and pleasure.

- Here too firmware and wiring go hand in hand, you pretty much have to have a detailed look at the firmware you are using before wiring anything. I provide my modification of the "ergodox-firmware" over here: https://github.com/BubblesToTheLimit/ergodox-firmware

- Some of the steps of this guide may not be described in much detail, but in contrast to option one there is a whole lot more of information.

Route 1: Dactyl Flexible PCB Rough Guide

For now, take a look at the images and try to figure things out, I know that's not great (it's better than nothing!)

Making the PCB

Get two sheets of 6in square Pyralux™. Use the Toner Transfer method to etch the Pyralux sheets as you would a usual PCB

NOTE: If you only have an Inkjet make photocopies of the print out, voilà Toner based copies!

Here'sa handy toner transfer guide …

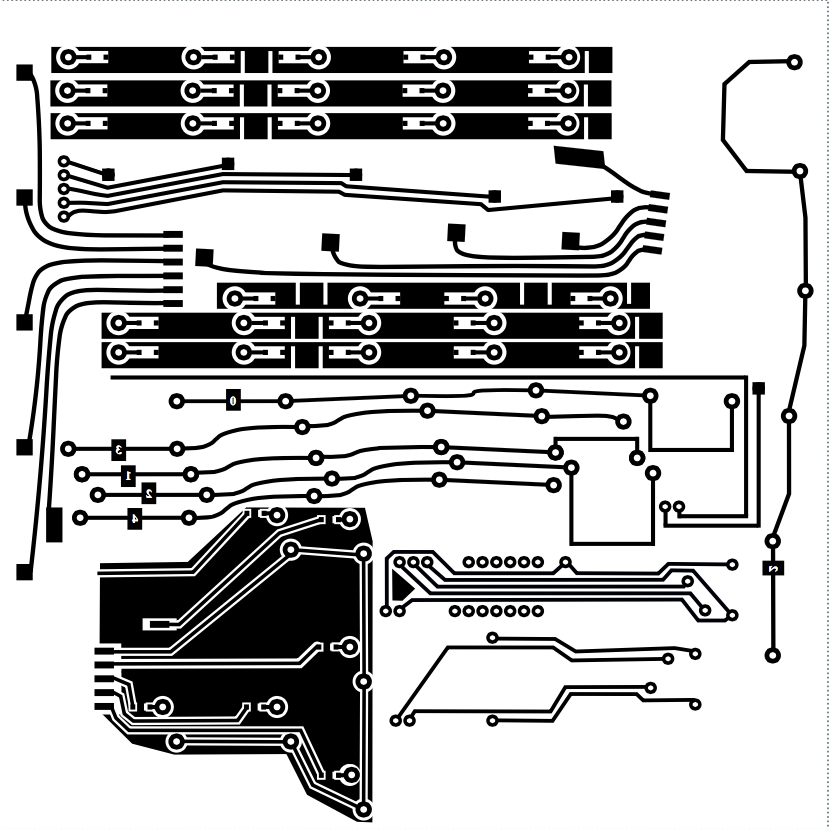

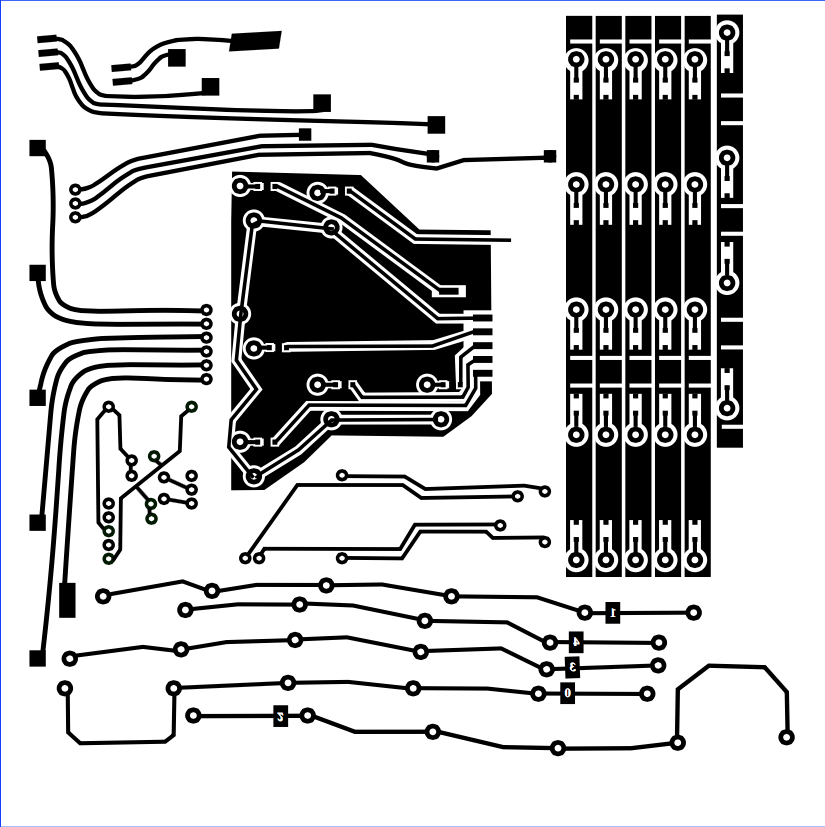

Print these PCB designs out…

Left hand:

Right hand:

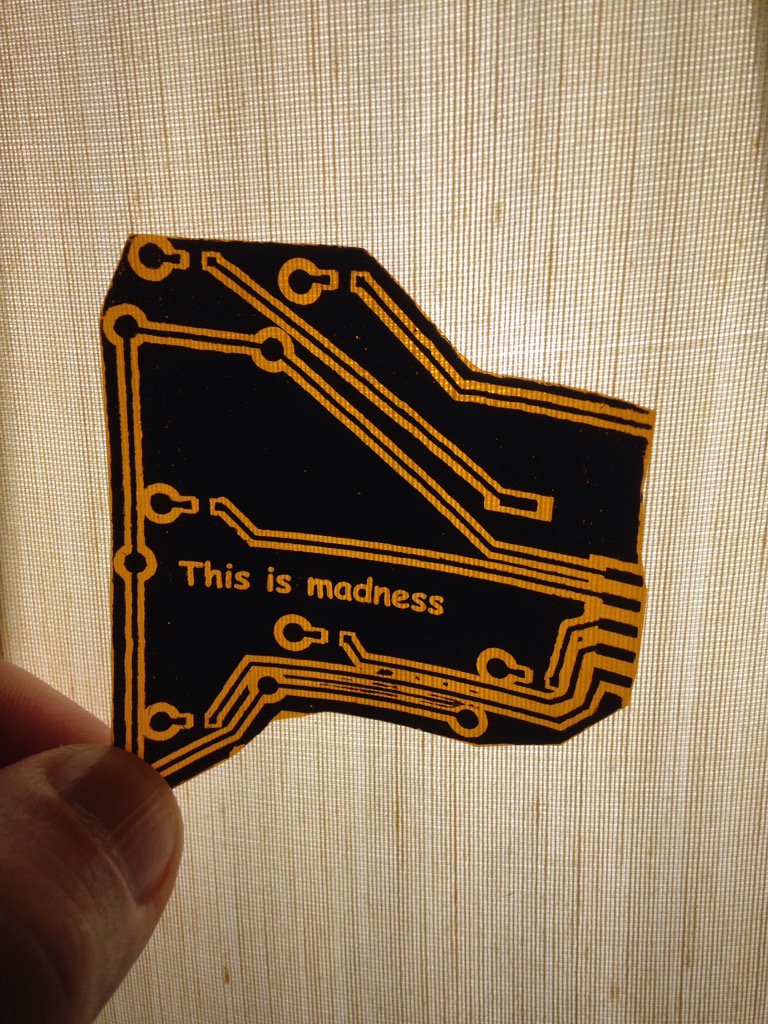

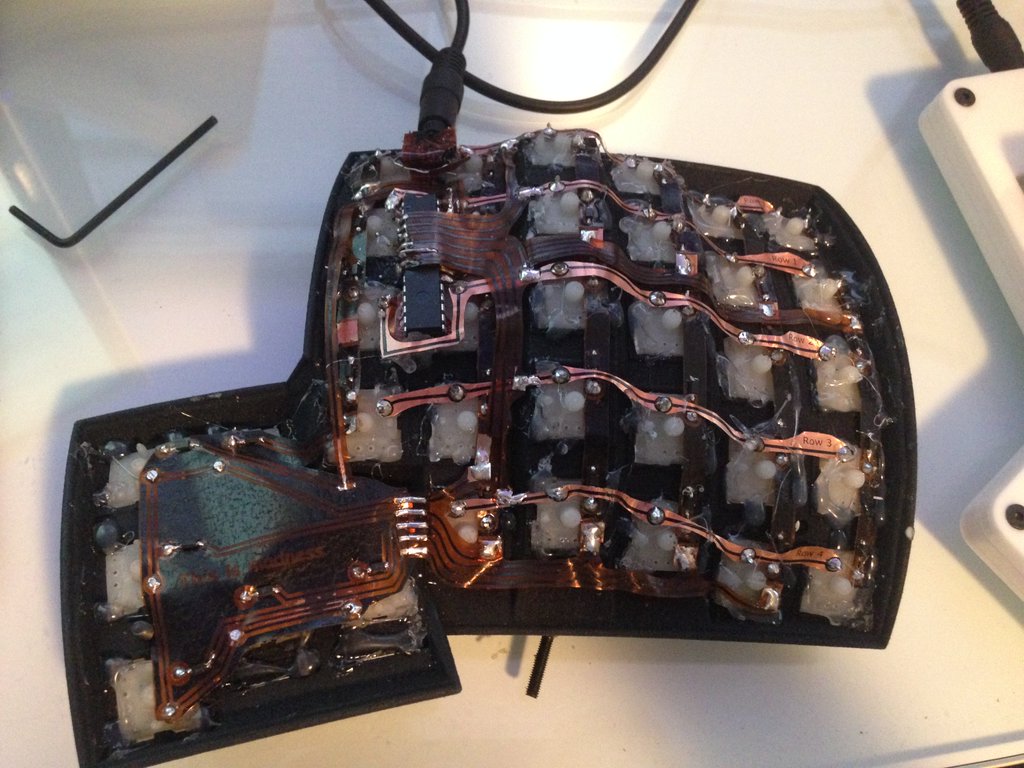

When you're done etching, you'll need to carefully cut the pcb into pieces… See the images below.

Applying the PCB to the electronical parts

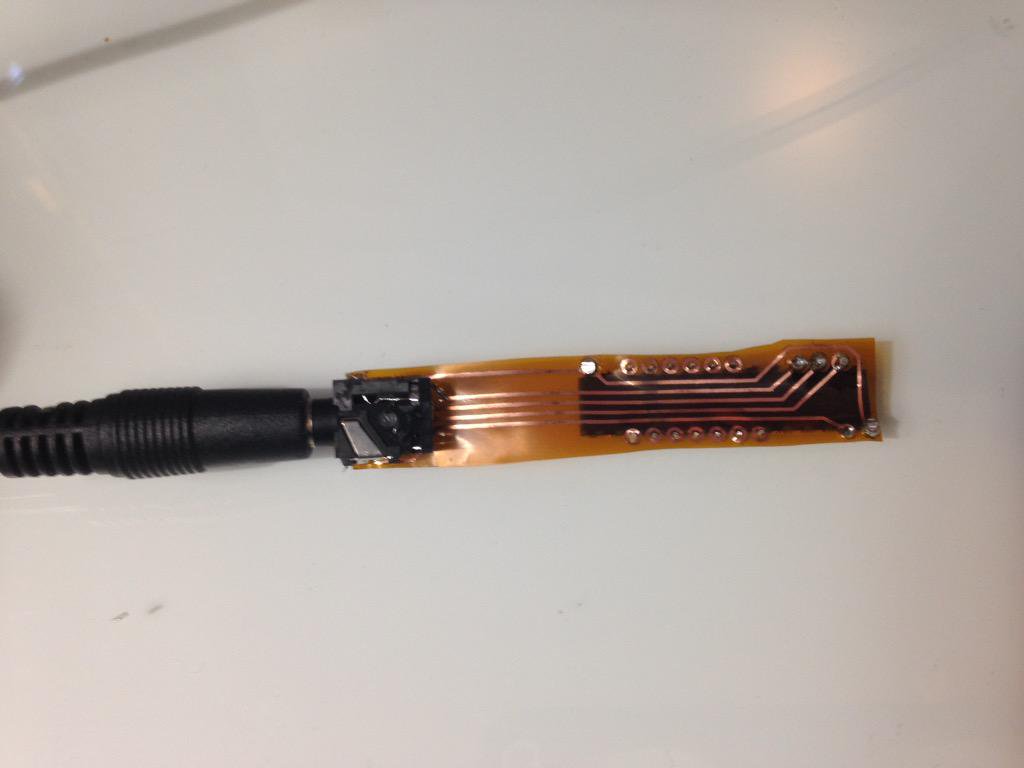

The thumb cluster pcb for the left hand:

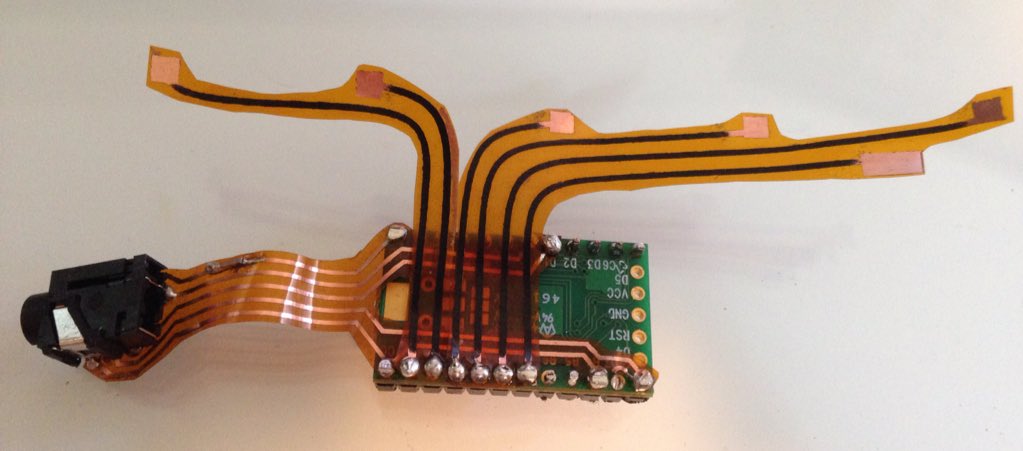

Solder the MCP like so:

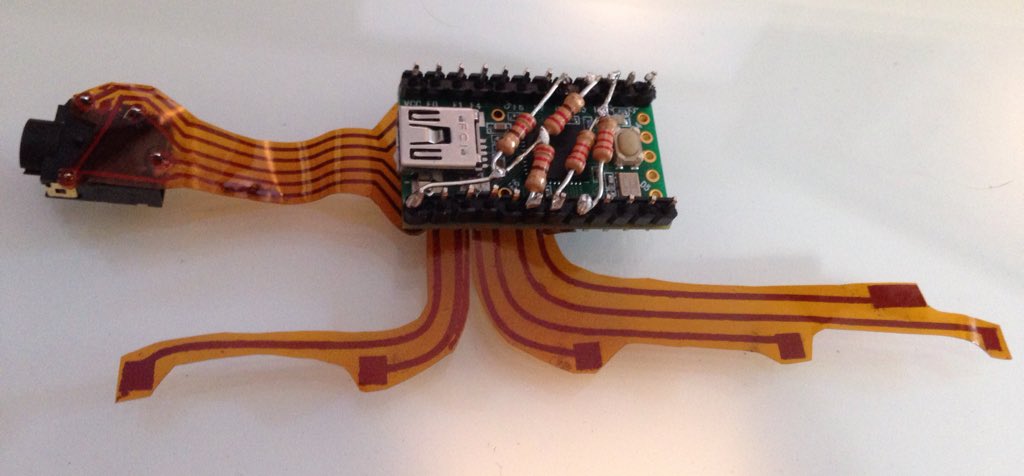

Solder the Teensy 2.0 like so:

Some interesting pull up 10k resistor business here… (TODO add a small diagram and notes)

Each hand of the keyboard will wire up like so:

Teensy goes here… note the rows soldered to the teensy via the Pyralux:

Here the left hand:

That's all for now, this guide will improve over time! (TODO!)

Route 2: Dactyl Hand-Wiring Guide

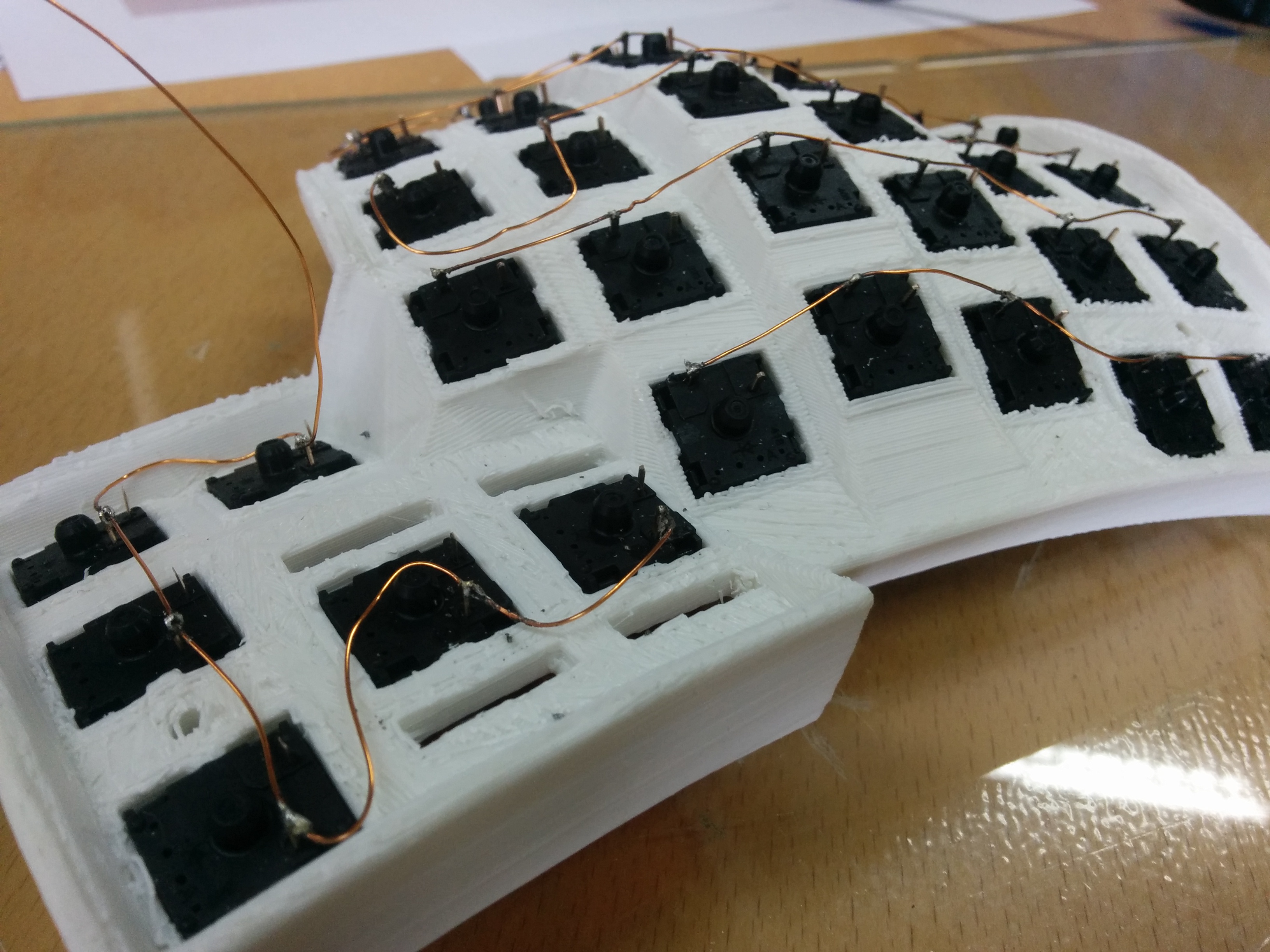

Step 1: Creating the rows

Using the copper wire you solder each row together, notice how the thumb-part gets its own row. If you take a close look you can see how I did do a messy job soldering, I had to redo some of the parts because they wouldn't be stable enough. Do this for both sides. Which ones of the pins you chose for the row doesnt matter, but for it to look clean you should decide for either one of them

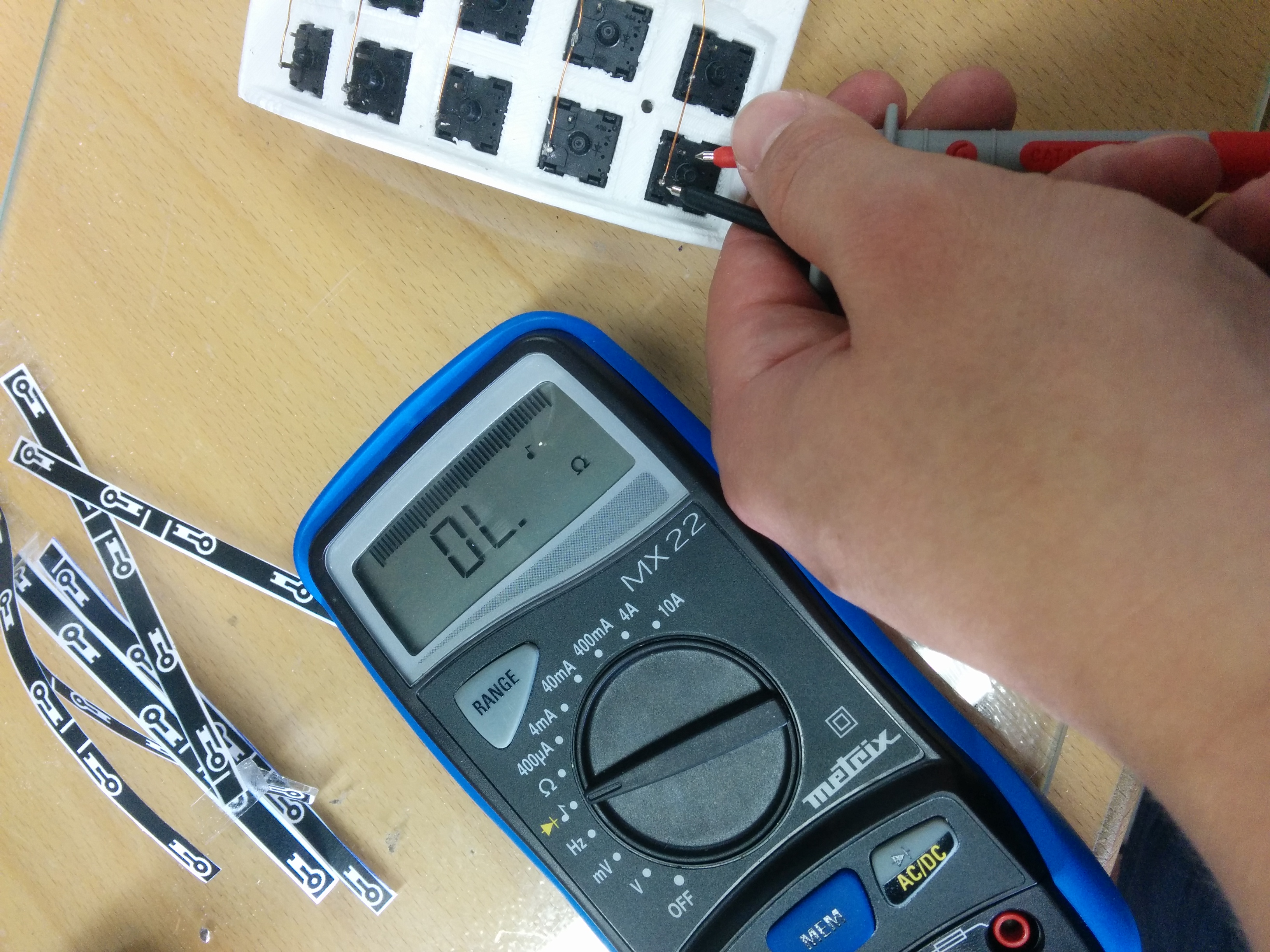

Because this was my first soldering job i went ahead and tested each one of the 70 switches.